The proportional fertilizer injector drives the piston or diaphragm through water flow to suck in the fertilizer solution according to the set ratio and mix it with the irrigation water. It has the characteristics of precise proportioning, no need for electricity, and easy operation. It can improve the efficiency and uniformity of fertilization and realize the integrated management of water and fertilizer.

The proportional fertilizer injection pump is directly installed in the water pipe, and the kinetic energy of the water flow in the pipe drives the pump to work. According to the set proportion, the higher concentration of medicine or fertilizer liquid is inhaled and fully mixed with the water in the main pipe before being transported to the downstream. And no matter how the water pressure and water quantity in the pipeline change, the absorbed dosage is always proportional to the volume of water entering the proportional fertilizer injection pump, so as to ensure a constant proportion in the mixed liquid.

Product Directions:

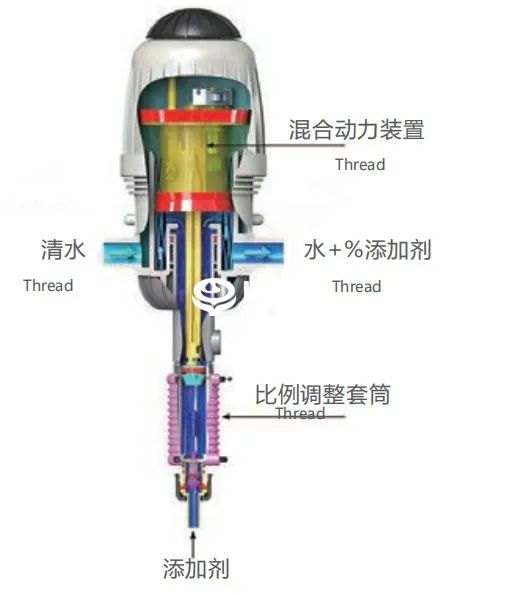

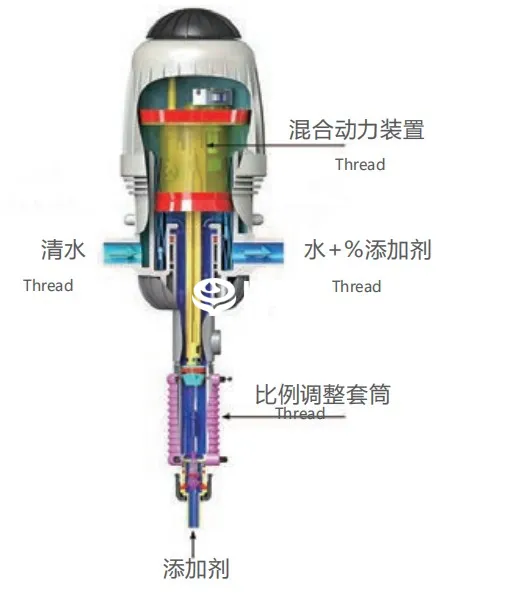

Operating principle:

When the water flow is connected in the pipeline, the equipment will start automatically, and when the water flow is interrupted, the equipment will stop automatically. If the product with on/of device is used, the action of extraction (suction) can be controlled.

Adjust the injection volume of mixrite proportional:

fertilizer injection pump by manually rotating the sleeve to the required proportion. The amount of concentrate injected is proportional to the amount of water passing through the mixrite proportional fertilizer injection pump.

Performance Highlights:

1.It is directly installed on the water supply pipe without electricity, and uses the water pressure as the working power. Easy to use, just turn on the water source.

2. Accurate proportion setting, not affected by water flow. "Proportionality" is the key to maintain a constant and accurate dose. No matter how the flow rate and pressure of the water change, the dosage of the solution is always strictly proportional to the amount of water entering the equipment.

3. It is easy to install and operate without the need of special person.

4. Excellent anti ultraviolet radiation performance, exquisite structure, high-quality plastic material with chemical corrosion resistance.

5. Various specifications and models, flow range of 0.02 ~ 25m3 / h, additive ratio of 0.1% ~ 10%, to meet your needs.

| Model number | Flow range | Working pressure(Mpa) | Injection ratio | Import and export dimensions |

| 2502 | 30-2500L/h | 0.02-0.8 | 0.3-2% | 3/4” |

| 2504 | 30-2500L/h | 0.02-0.8 | 0.4-4% | 3/4” |

| 2506 | 40-2500L/h | 0.02-0.8 | 6% | 3/4” |

| 2508 | 20-2500L/h | 0.02-0.8 | 0.1-0.9% | 3/4” |

| 2510 | 50-2500L/h | 0.02-0.8 | 3-10% | 3/4” |

| 2512 | 2500L/h | 0.02-0.8 | 0.3-2% | 3/4” |

| 2514 | 2500L/h | 0.02-0.8 | 0.4-4% | 3/4” |

| 2516 | 2500L/h | 0.02-0.8 | 6% | 3/4” |

| TF10-001 | 0.5-10m³/h | 0.1-0.8 | 0.1-1% | 1” |

| TF10-002 | 0.5-10m³/h | 0.1-0.8 | 0.2-2% | 1” |

| TF10-005 | 0.5-10m³/h | 0.1-0.8 | 1-5% | 1” |

| TF25-001 | 2-25m³/h | 0.1-0.8 | 0.1-1% | 2” |

| TF25-002 | 2-25m³/h | 0.1-0.8 | 0.3-2.5% | 2” |

| TF25-005 | 2-25m³/h | 0.1-0.8 | 1-5% | 2” |

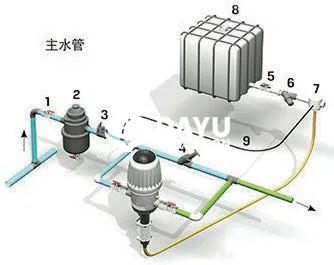

INSTALLATION METHOD

Typical bypass installation when using large fertilizer tank:

1. Main valve 2. Filter - 120 mesh

3. Pressure regulating valve 4. Throttle valve

5. PVC plastic valve 6. Fertilizer filter

7. Normally closed hydraulic driven safety valve 8. Fertilizer container

9. 5/16 command tube

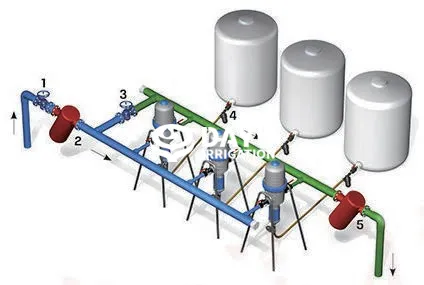

Multi bypass installation mode:

1. Main valve 2. Main pipe filter

3. Throttle valve 4. Fertilizer solvent filter

5. Filter after mixing