All the machine works in linear movement by motor driven tires to irrigate rectangle area, this system is called lateral move system or linear system.Unlike center pivot systems, where the areairrigated is dependent only on the length of the machine, lateral system area is determined by two factors: system length and travel distance.

The lateral movement system is the only machine that can irrigate all crops. All spans are consistent with the ground and there is no wind angle. The irrigation rate can be increased to 99%.

Suitable crops:cereals, vegetables, cotton, sugar cane, pasture and other economic crops.

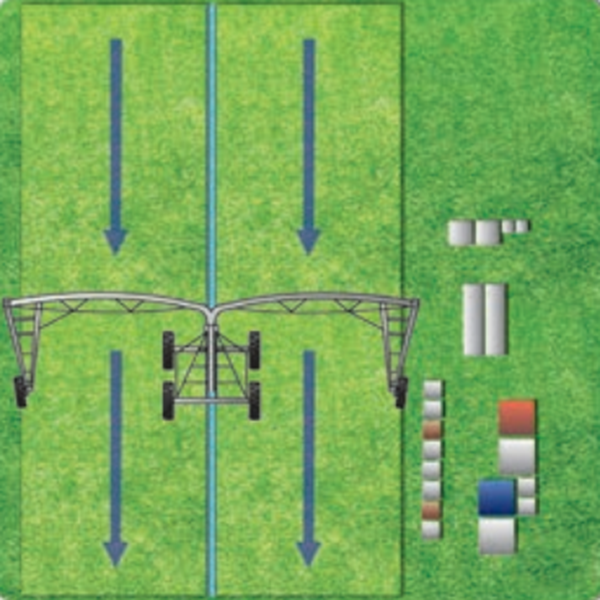

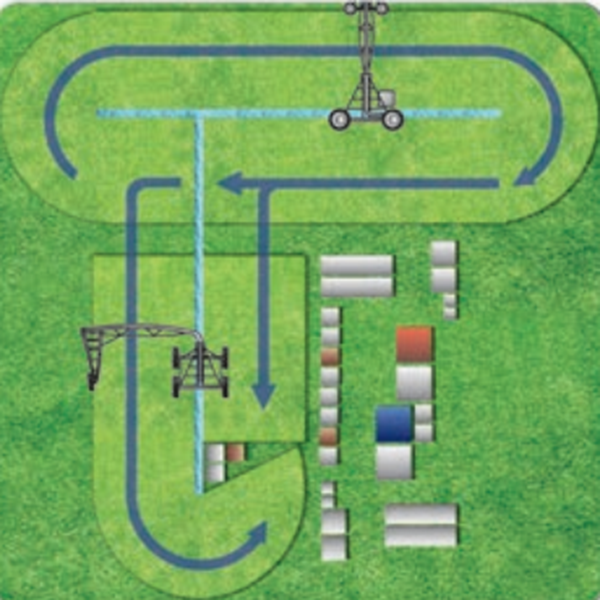

Equipment running trajectory

Translational. The center point and all spans move parallel to each other, and the water flows from the center point through the uniformly distributed nozzles on the body to irrigate the ground. Suitable for irrigating long plots of land.

Double Cantilever Lateral move System

Single Cantilever Lateral move System

There are two ways of water supply: channel water supply and pipeline water supply.

The following factors should be considered in the design of translational sprinkler irrigation machine:

A. Water source: well output / pump power.

B. Water conveyance mode: canal specification / canal overflow and spillway.

C. Sprinkler system: pipe size / power supply / pump / generator.

Equipment length

Unit span length 50m, 56m or 62m; cantilever lengths of 6m, 12m, 18m and 24m are available; optional tail gun can be installed. The maximum length of the equipment is related to the type of equipment, water supply, power supply and guidance method.

Power and water supply

Power supply method: generator set or dragging cable; water supply method: dragging pipe water supply, canal feeding water supply.

Main features

Comparison with other forms of irrigation; robust, easy to manage and highest irrigation uniformity.Comparison with large circular machines: 98% plot utilization rate; higher equipment purchase cost;mostly diesel generator power supply, higher operation and management cost; more complicated water and electricity supporting facilities; long irrigation cycle time.

Product features

Wide coverage and flexible movement, single unit can control 200 hectares of land, high degree of automation, simple operation, very low electricity consumption, low labor costs.

Uniform irrigation, spraying uniformity coefficient up to 85% or more, low investment cost, service life of 20 years.

It can be selected from 1 span to 18 spans, but it is generally more economical to have more than 7 spans.

Using the same quality of UMC VODAR motor, its adaptability to the environment, extreme cold and heat are not affected, low failure rate, low maintenance rate, safe and reliable.

With protection function, for the voltage instability and overload situation, will not appear fuse, broken wire phenomenon.

Using aluminum alloy shell, can effectively waterproof sealing.

The motor is well sealed, no oil leakage, long service life.

Adopt the same quality VODAR reducer of UMC, which is suitable for different field conditions, safe and reliable.

Box type input and output oil seal, effectively prevent oil leakage.

External dustproof protection for both input and output shafts.

Stainless steel full circulation expansion chamber, using extreme pressure gear oil, the worm gear lubrication protection performance is remarkable.

Cross-body connection adopts the ball and cavity connection method, and the ball and cavity tubes are connected by rubber cylinders, which has strong terrain adaptability and greatly improves the climbing ability.

The ball head is directly welded to the short cross body pipe, which greatly increases the strength and can cope with the tensile force of steel in cold weather conditions and avoid collapse of equipment.

The tower is V-shaped, which can effectively support the truss and greatly improve the stability of the equipment.

Double fixation is used at the connection of tower leg and pipe, which greatly improves the running stability of the equipment.

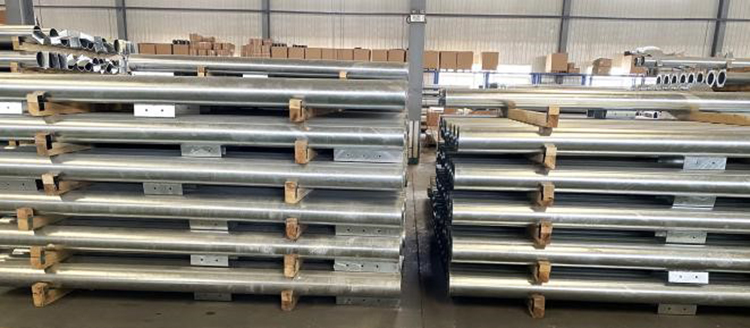

The pipe is made of Q235B, Φ168*3, with thickening treatment to make it more stable, impact resistant, low temperature resistant and tough.

All steel structures are hot-dip galvanized in one go after processing and welding, and the thickness of galvanized layer is 0.15mm, which is much higher than the industry standard, with high corrosion resistance and service life of more than 20 years.

After processing, each main tube is tested by the drawing machine for its welding strength to ensure 100% qualification rate.

The control system adopts American Pierce technology, which is stable and reliablewith rich functions.

Key electrical components use American HoneyWell and French Schneider brands to guarantee stable equipment operation performance.

With rainproof function, the keys have dustproof treatment, which greatly prolongsthe service life.

Before leaving the factory, strict testing is carried out to ensure the stability of the entire control system.

Cross-body cable adopts three-layer 11-core pure copper armor cable, with strong shielding signal performance, so that multiple devices running at the same time will not interfere with each other.

The motor cable adopts three-layer 4-core aluminum armored cable.

The outer layer is made of high-density natural rubber, which is resistant to high temperature, ultraviolet rays and aging.

Using natural rubber, anti aging, wear resistance;

Special 14.9-W13-24 tire for large pattern irrigation, with herringbone facing outward and strong climbing ability.

Nelson D3000 and R3000 and O3000 series and I-Wob serie.

Instantaneous irrigation intensity is an important factor to consider when designing sprinkler heads and is related to the permeability of the soil. General nozzle design to achieve both the crop's water requirements and less than the maximum infiltration of soil water to avoid waste of water and fertilizer runoff. The instantaneous irrigation intensity of the smaller sprinkler for the soil and crop applicability is stronger.